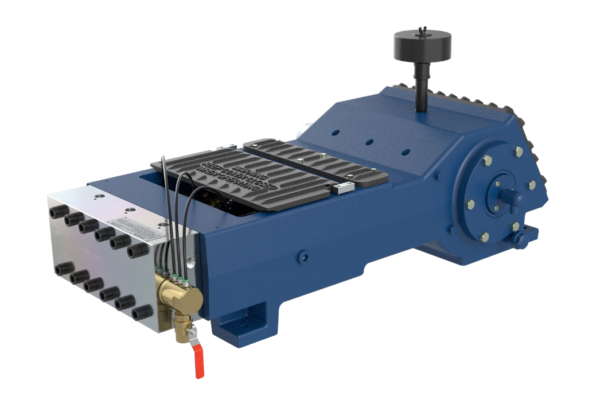

S300

This system has enhanced the power from its Aqua-Dyne affiliate, a proven design already, by upgrading the power frame and cross heads to a much stronger material, ductile iron. Also, now our bare shaft pumps feature a crankshaft machined from billet and are drilled for forced lubrication.

We will offer two models, the S300-15 and the S300-20, capable of handling pressures to 15,000 and 20,000 psi respectively. Both bare shaft pumps feature hinged manifolds for easy access to the quick change valve cartridges, plungers and stuffing boxes.

Flow rates: 48 GPM @ 9,000 psi / 26 GPM @ 15,000 psi / 20 GPM @ 20,000 psi

Crankshaft machined from billet, with induction hardened journals

Forced lubrication for crankshaft

High strength ductile iron power frame

Hinged cover to pump well

Quick change convertible manifolds from 15,000 to 20,000 psi

Hinged trunnion assembly for swing down manifold

Quick change cartridge assembly for suction and discharge valves

S50 BARE SHAFT PUMP

The key to this pumps long lasting capabilities and hundreds of hours of trouble-free operation are that it offers low load packing, special filtration, a closed loop non-drip cooling and water lubrication system for alumina ceramic or tungsten carbide plungers.

The individual lightweight suction and discharge manifolds are easily removed for routine maintenance, and field changing the packing or plungers takes five minutes with no special tools required.

Number of Cylinders: 3

Plunger Strokes: 1.97"

Plunger Load: 3,800 lbs

Oil Capacity: 1 Gallon

Pump Weight: 130 lbs

Unique "Valve-In-Line" Fluid Ends design provides higher volumetric efficiency for increased productivity & lower operating costs.

FLUID END SPECS

POWER END

S/M

L/XL

XXL/XXXL

Aqua Safe Bibs/Overalls P/N AQSB1

S/M

L/XL

XXL/XXXL

Foot Covers P/N AQSF1-PR

One Size -Pair

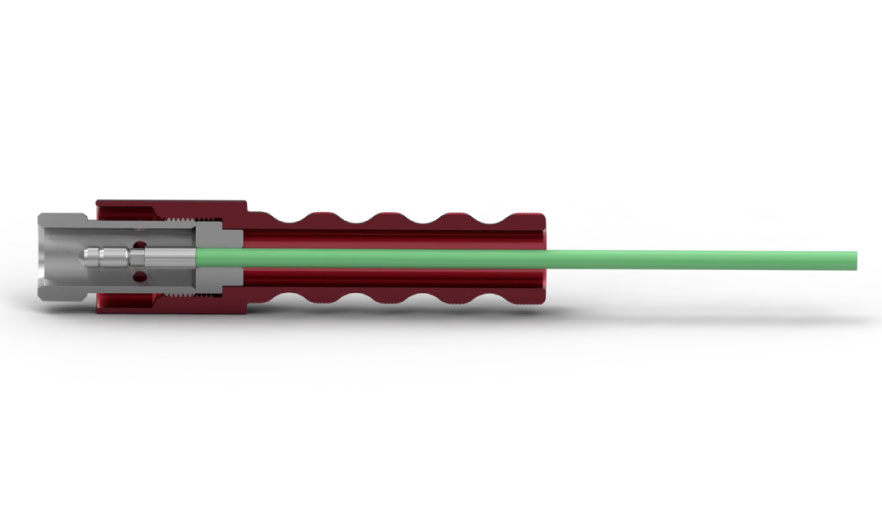

FLEX LANCE SAFETY GRIPS

10-15K psi FLEX LANCE SAFETY GRIPS

The Flex Lance Safety Grip is designed to minimize the risk on injury to flex lance operators caused by a live nozzle exiting the tube unexpectedly. The comfortably contoured handle makes it easy to hold the safety grip against the tube sheet, allowing retraction of an active nozzle in to a stainless steel sleeve,where the force of the jets is dissipated.

The Flex Lance Safety Grip is simple to install and is quickly adapted to handle various lance sizes by selecting the appropriately sized lance stop.

(Note: the larger diameter end of the lance stop must be next to the end fitting.)

Contact us today

Call us at

(832) 663-6280

Our office

Waterjet Technologies, LLC

118 Vintage Park Blvd

Ste. W122

Houston, TX 77070